Design points of SMC molded products' external shape

For the design of SMC molded products, not only the shape and structure of SMC products should be determined according to the quality requirements of SMC products and the working conditions of bearing loads, but also each process should be analyzed and weighed according to the actual situation of molding production, so that the products can meet the technological requirements of molding manufacturing.

The design structure of SMC products is mainly reflected in the mold design and the implementation of process conditions in the molding process.

In the design of SMC molded products, we should pay attention to the influence of mold on products. In many cases, groove, platform and concave convex are inevitable in the shape structure, which will not only complicate the mold manufacturing, but also affect the yield because of the zigzag flow direction of the molding material in the molding process. Therefore, in the shape design of SMC products(especially for products with high strength requirements), it is necessary to reduce the flow direction twists and turns in the molding proces. In addition, the surface quality of the products is poor and the strength is decreased. Therefore, in the design of SMC molded products, the sharp corner should be rounded, and the radius should be increased as much as possible without affecting the appearance ans use requirements.

For the design of SMC molded products, not only the shape and structure of SMC products should be determined according to the quality requirements of SMC products and the working conditions of bearing loads, but also each process should be analyzed and weighed according to the actual situation of molding production, so that the products can meet the technological requirements of molding manufacturing.

The design structure of SMC products is mainly reflected in the mold design and the implementation of process conditions in the molding process.

In the design of SMC molded products, we should pay attention to the influence of mold on products. In many cases, groove, platform and concave convex are inevitable in the shape structure, which will not only complicate the mold manufacturing, but also affect the yield because of the zigzag flow direction of the molding material in the molding process. Therefore, in the shape design of SMC products(especially for products with high strength requirements), it is necessary to reduce the flow direction twists and turns in the molding proces. In addition, the surface quality of the products is poor and the strength is decreased. Therefore, in the design of SMC molded products, the sharp corner should be rounded, and the radius should be increased as much as possible without affecting the appearance ans use requirements.

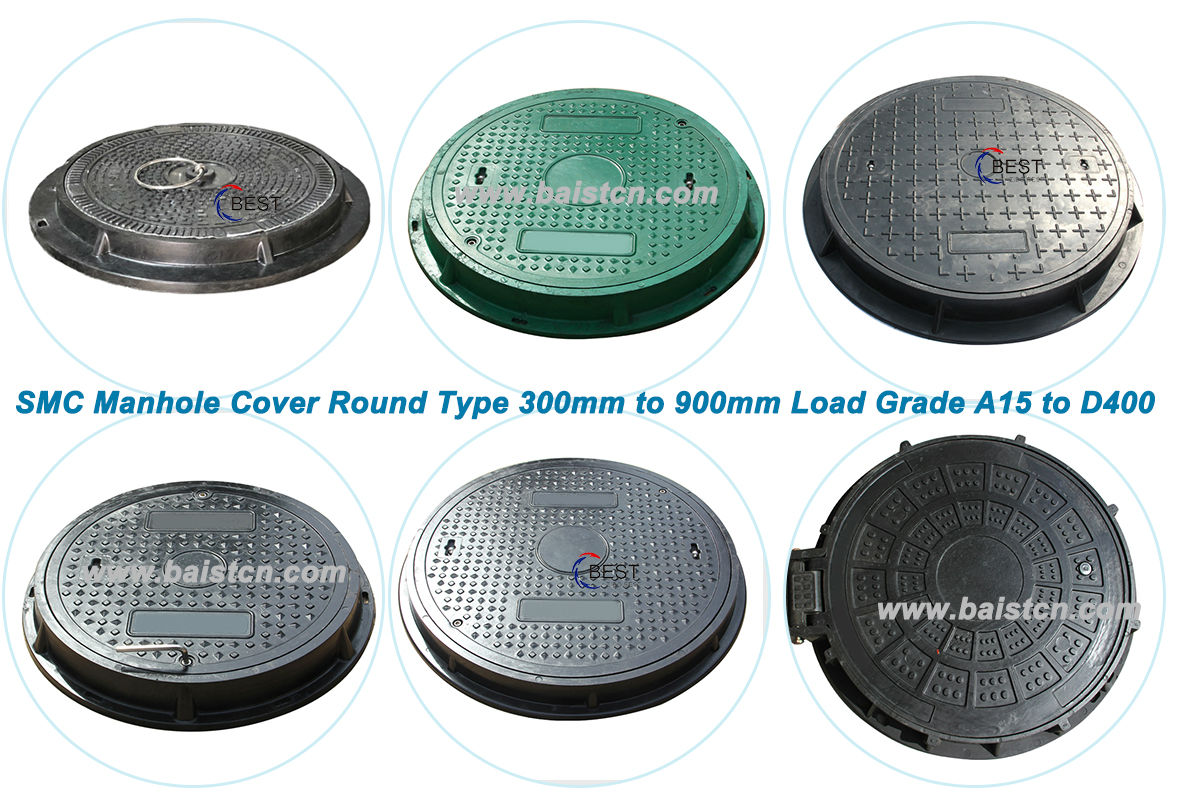

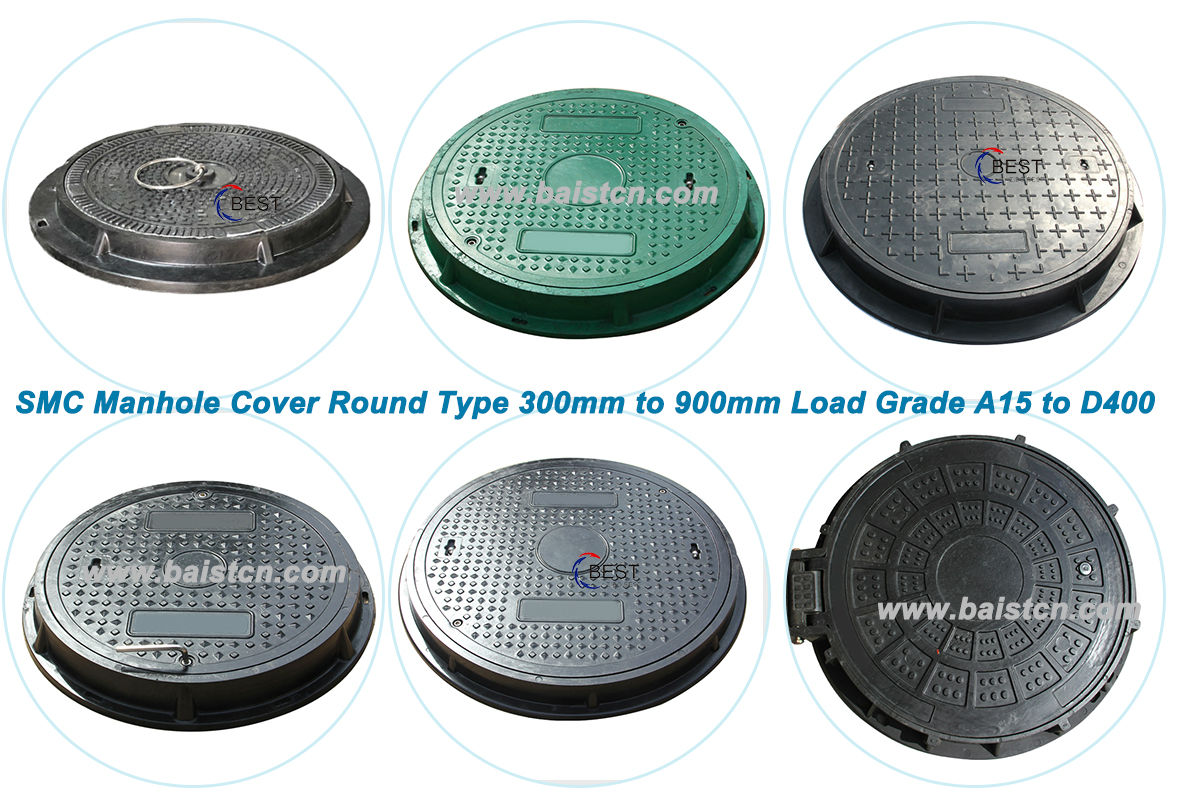

Zibo Best Energy-saving Materials Co., Ltd. was established in 2004, specialize in producing and supplying manhole cover, drain grating ,tree-grating, gully grating. Strictly in accordance with BS EN124 and have obtained various kinds of certificates. Till now, our competitive products not only have good market in domestic, but also owned a large overseas market with a high reputation.