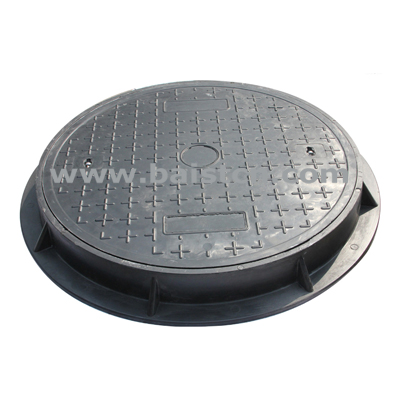

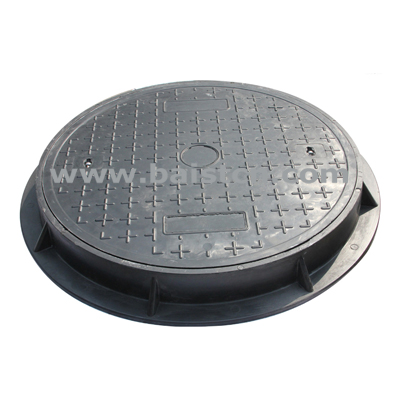

With the development of urban construction, the rise of engineering projects such as old village renovation and demolition of old buildings has increased the demand for manhole covers. Compared to traditional metal cast iron manhole covers, noise problems and theft have seriously affected our daily travel safety. It has also become a problem for various construction departments. The composite manhole cover uses polymer composite material and unsaturated resin as the main materials. After high temperature molding, it is molded once. After molding, it not only has high strength and beautiful appearance, but also has good waterproof, flame retardant, wear resistance, pressure resistance, antistatic, Corrosion resistance and aging resistance are ideal substitutes for cast iron manhole covers. Resin composite manhole covers can also be customized and customized. Different specifications, different styles, and different colors can be produced according to user needs, which not only meets the needs of users, but also suits the installation environment. It is also very advantageous in terms of service life. Compared with traditional manhole covers, it is light in weight, strong in toughness, will not rust, and will not be stolen, and it will not have noise problems such as "running, jumping, ringing, etc." It can generally be used for 15-20 years. It will not generate sparks due to impact during installation and use. Especially in flammable and explosive environments such as gas stations, composite manhole covers must be used, which can meet the requirements of gas stations. Demand can also reduce the occurrence of dangerous accidents. It is precisely because of these properties that it can occupy a place in the highly competitive market. It is believed that it will go further and further in the future, and it will be accepted by more users.